ALBAPLANT MANUFACTURES

HEAT TREATMENT FURNACES

FOR EXTRUSION DIES:

–GASEOUS NITRING

–DIE PREHEATING WITH

INDIVIDUAL TRAYS

ALBAPLANT MANUFACTURES

HEAT TREATMENT FURNACES

FOR EXTRUSION DIES:

–GASEOUS NITRING

–DIE PREHEATING WITH

INDIVIDUAL TRAYS

ALBAPLANT MANUFACTURES

HEAT TREATMENT FURNACES

FOR EXTRUSION DIES:

–GASEOUS NITRING

–DIE PREHEATING WITH

INDIVIDUAL TRAYS

GAS NITRIDING

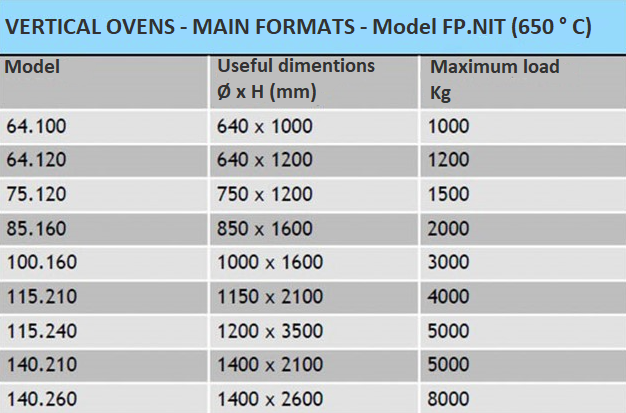

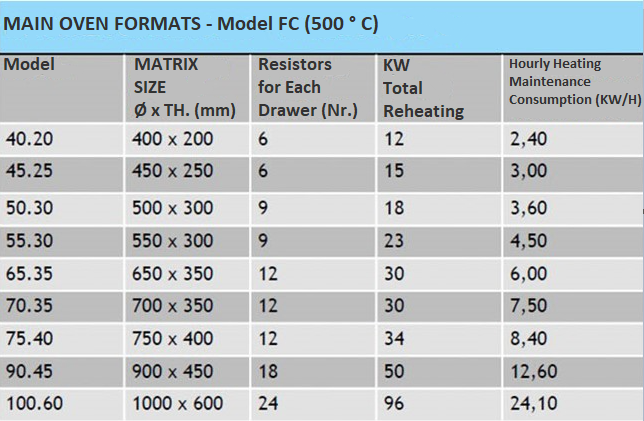

ALBAPLANT produces controlled atmosphere gas nitriding heat treatment furnaces in two model geometries, vertical pit and horizontal chamber furnaces, for small to large volume applications with high quality standards. In a range of typical sizes or specials on request.

MATRIX TREATMENT

We specialise in gas nitriding treatment for dies with a wealth of experience made available to all our customers, with proven success at the most important extruders in Italy and abroad.

TYPICAL TREATMENTS

• Gas nitriding treatment

• Nitrocarburisation treatment

• Low-pressure nitriding treatment

• Preoxidation treatment

• Post-oxidation treatment

FEATURES

• Integrated heating and cooling cycle

• High reliability of heating elements

• Atmosphere analysis system and automatic control

• Modular and ergonomic workpiece holder

• Emissions according to current standards

• Remote assistance and remote surveillance

WITH OUR SUPPLY YOU WILL HAVE

• Uniformity within the boiler of +/- 3°C or better.

• Process security.

• Traceability of parameters all recorded on PC.

• High-level diagnostics.

• Our know-how for nitriding and nitrocarburising processes, the result of decades of experience in the industry, is made available to all our customers.

• Unique process regulation and control system for both top-loading and horizontal shaft kilns.

• High level of control panel construction and safety.

OUR RANGE

ALBAPLANT produces controlled atmosphere gas nitriding furnaces with high quality standards mainly in two model geometries, horizontal chamber furnaces and vertical shaft furnaces.

Our range includes a number of standard size models and any specials on request

HIGH LEVEL OF THE PROCESS

The process control system developed by ALBAPLANT automatically analyses and continuously corrects the inlet flow ratios of technical gases, ensuring that the desired hardness settings are maintained. This control automatically takes into account changes in the active surface of the parts being treated. Our systems can be supplied on request with CQI9 Compliant control system. Emissions to current standards.

TECHNICAL GAS MIXING CABINET

Innovatively constructed with a high technological content, the ALBAPLANT gas panel is ergonomically designed and easy to maintain.

Our gas mixing system, compared to conventional gas mixing systems, results in much lower ammonia consumption and emissions. Our control allows consumption data per cycle of technical gases and energy to be analysed and stored and included in the calculation of treatment costs.

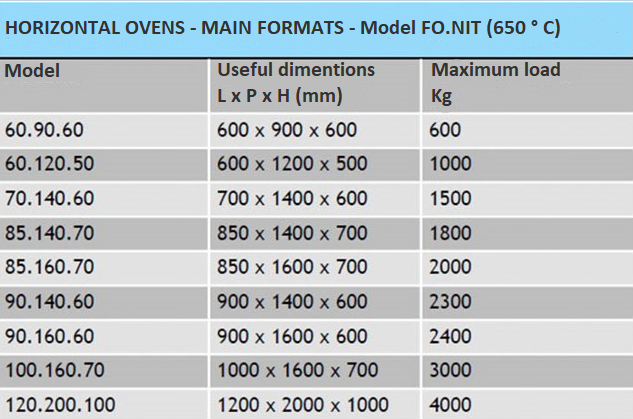

COMPLEX AND AUTOMATIC LINES

The horizontal chamber oven lends itself to automatic line installations with automated loading and unloading from a shuttle.

The automatic lines can be integrated with horizontal furnaces of other heat treatments of our own production and with the integrated control of our advanced general supervisor.

ALBAPLANT designs and builds single plants and automatic lines all on a turnkey basis:

• Nitriding furnaces

• Tempering and/or Preheating Furnaces

• Spray/immersion washing machine

• Single- and double-decker storage pallets

• Automatic loading/unloading shuttle

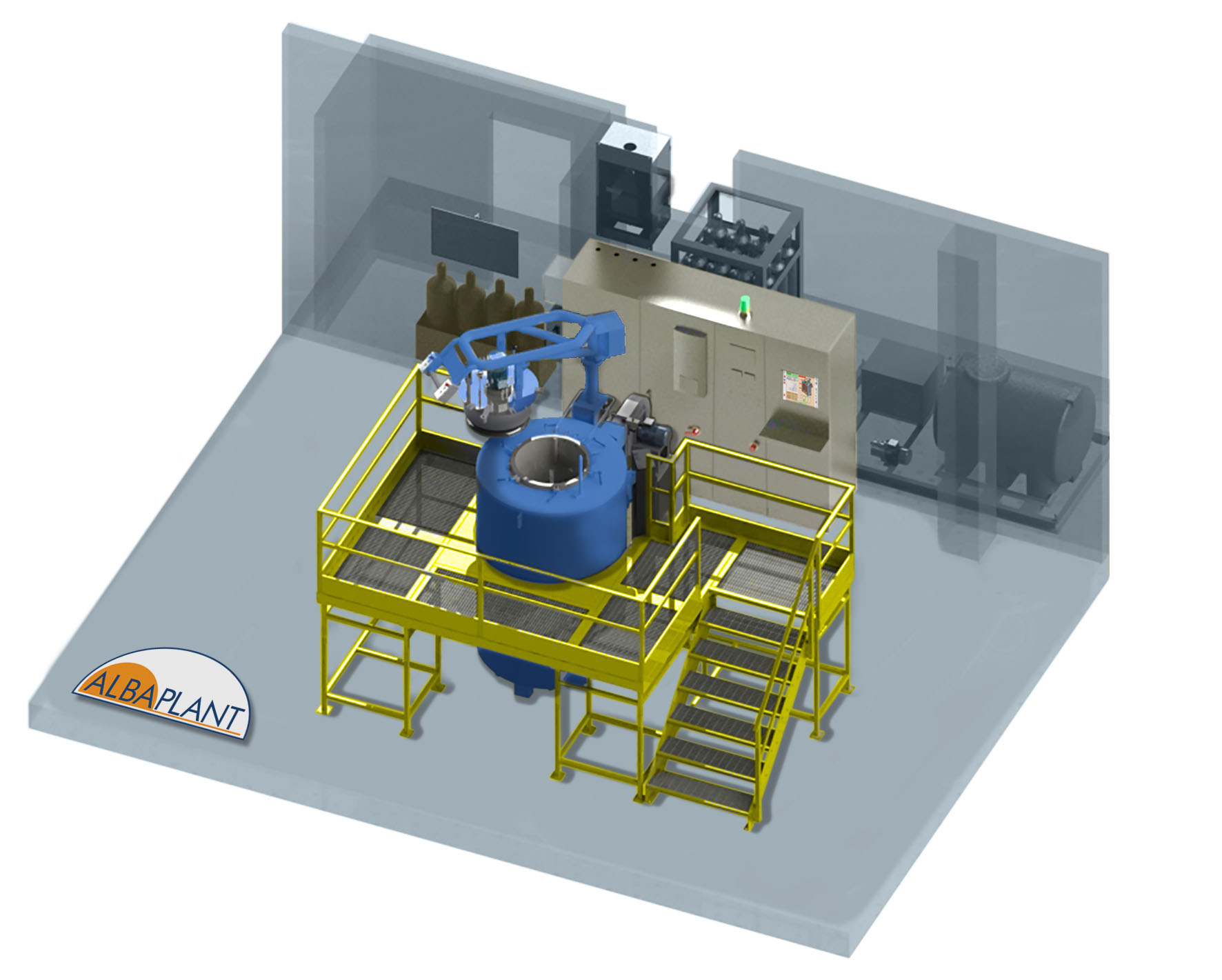

DIE PREHEATING FURNACES

ALBAPLANT manufactures individual tray preheating furnaces with unique experience gained over 30 years in the industry, with excellent quality standards in a wide range of geometries. An important experience made available to all our customers, with a proven success at the most important extruders in Italy and abroad.

TYPICAL TREATMENTS

• Versions with pre-vacuum and protective atmosphere (nitrogen)

• Versions with protective atmosphere (nitrogen)

• Versions in air

• Forced ventilation on main models

FEATURES

• Systems arranged for robot stations

• Nitrogen-tight chamber

• Low nitrogen consumption

• Low residual oxygen

• Low energy loss

• Dual temperature control

• In-line or stacked tray version

Request information on ALBAPLANT products

Our technical experts are always available at Your disposal for any need