ALBAPLANT manufactures

VACUUM HEAT TREATMENT FURNACES

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

ALBAPLANT MANUFACTURES

VACUUM HEAT TREATMENT FURNACES

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

ALBAPLANT MANUFACTURES

VACUUM HEAT TREATMENT FURNACES

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

IN A WIDE RANGE OF GEOMETRIES

AND SIZES FOR SMALL

TO LARGE VOLUME APPLUCATIONS

WITH HIGH QUALITY STANDARDS

EMPTY FURNACES

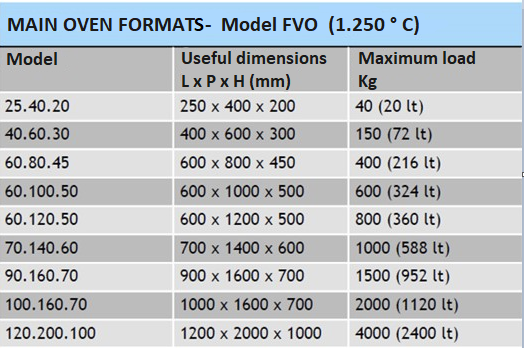

OUR RANGE

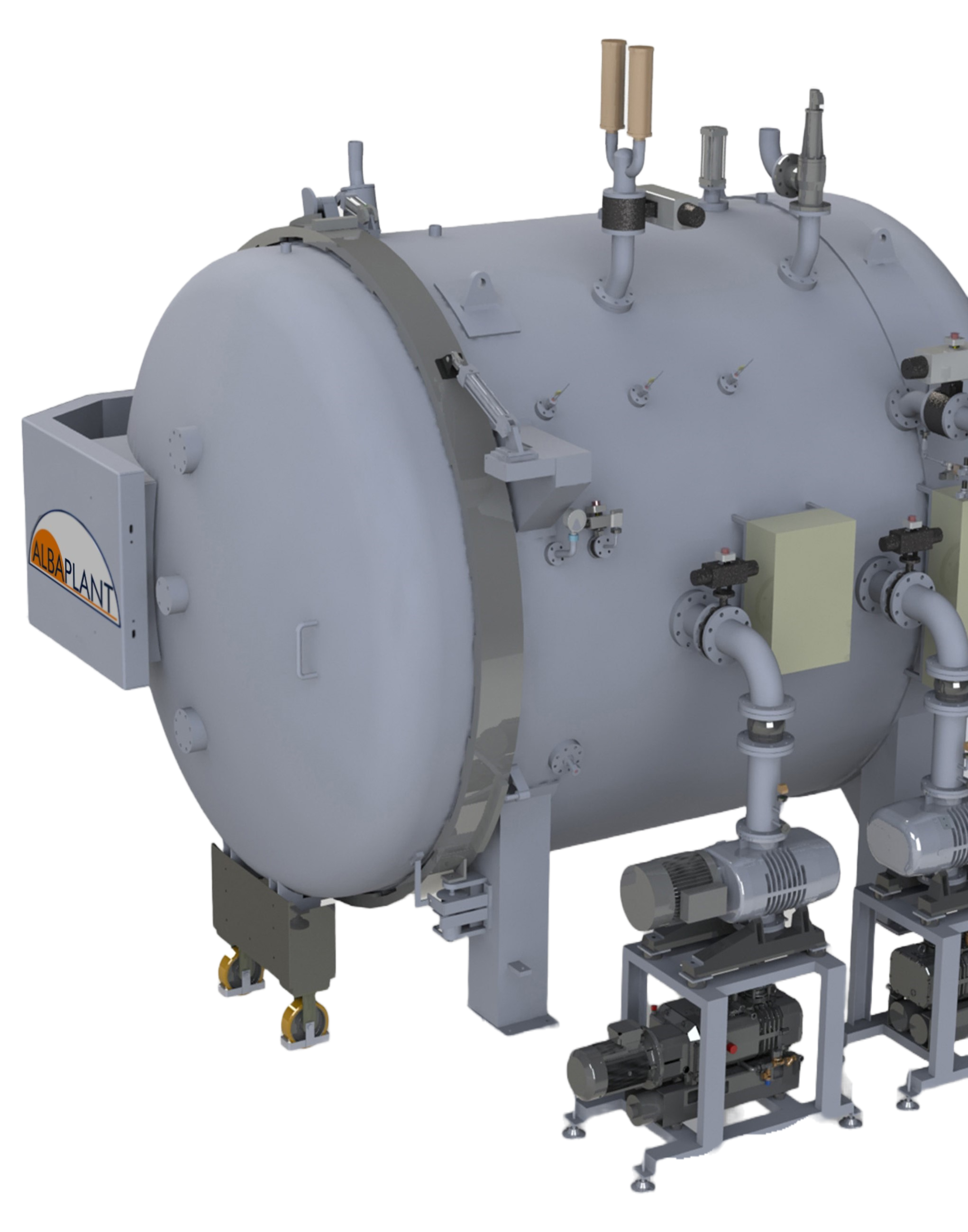

Albaplant’s standard vacuum oven is equipped with technical and performance features that meet automotive, aerospace and aeronautical market standards.

Examples are the SAT and TUS equipment required by AMS-2750 and the CQI-9 COMPLIANT control system. Our software is not only very user-friendly, but also provides access to all special settings.

TYPICAL TREATMENTS

• Our software is not only very user-friendly, but also provides access to all special settings.

• Vacuum brazing: steels, aluminium, titanium.

• Vacuum sintering: steels, titanium, ceramics.

• Vacuum treatments: annealing, normalisation, stress relief and tempering.

FEATURES

• Integrated heating and cooling cycle

• Carbon fibre process chamber

• High reliability of heating elements

• High-efficiency pumping system

• Emissions according to current standards

WHAT YOU GET

• Process repeatability and reliability

• Immediacy in reading information

• Low and easy maintenance

• Possibility of customising cycles ‘in house’

• Remote assistance and remote surveillance

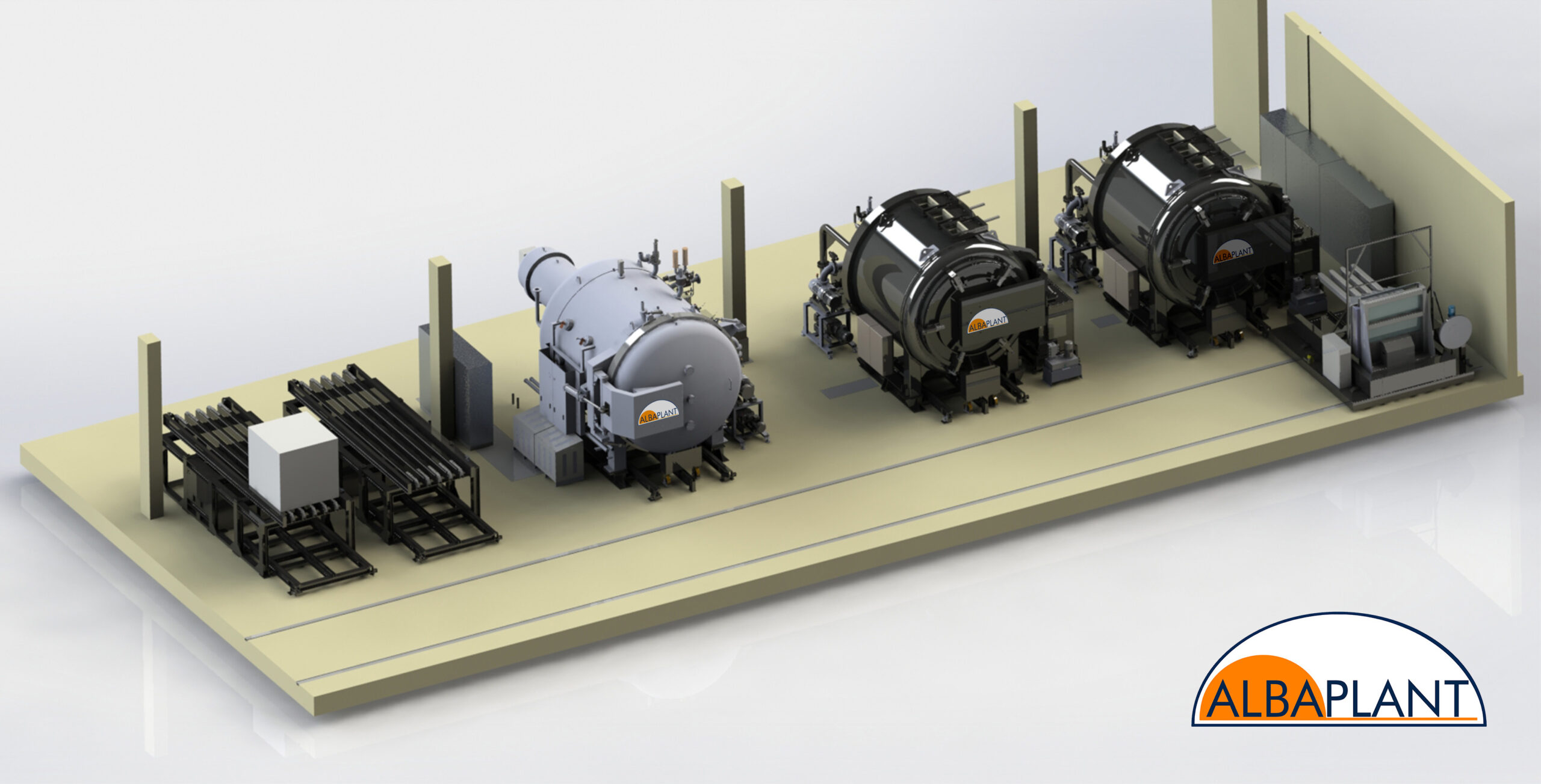

TURNKEY INSTALLATIONS

ALBAPLANT designs and builds single plants and automatic lines all on a turnkey basis. Our turnkey vacuum processing system is much more than a standard oven with controls. An integrated system that starts with evaluating with the customer the best application in accordance with their production requirements. It then continues with on-site installation and commissioning, personnel training, process testing and the development of customised recipes. It then continues with on-site installation and commissioning, personnel training, process testing and the development of customised recipes. To which we add our after-sales services.

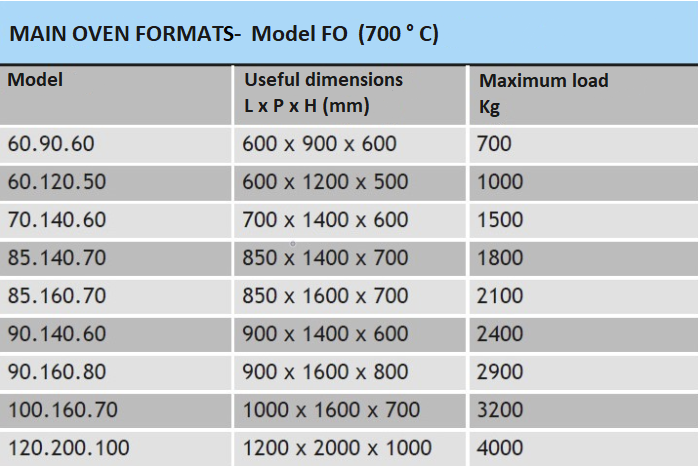

PRE-VACUUM FURNACES

We produce tempering furnaces in various construction geometries, with high quality standards for treatment in an inert, controlled atmosphere, i.e. in the presence of pure nitrogen and less than 5 parts per million oxygen.

In a range of standard and special sizes on request.

TYPICAL TREATMENTS

• Tempering Treatments

• Blank annealing

• Stress relieving and normalising

FEATURES

• Temperature uniformity with a tolerance of ± 3°C

• Temperature uniformity with a tolerance of ± 3°C

• Exclusive regulation and control system

High level of process repeatability

Our furnaces are designed to operate via ‘PC’ for total control of the process and the charge being processed.

Request information on ALBAPLANT products

Our technical experts are always available at Your disposal for any need